TUNGLI ELECTRONIC has research and development divisions totaling more than 50 personnel located at both the Taipei head office and the production facilities at LIWEI (Dongguan) ELECTRONIC providing a high quality service to meet the exacting demands of customers with the company concept of “Service care and innovation” and strive to constantly improve the value of the service, paying close attention to current and developing industry trends. We pride ourselves on our sustained efforts in the field of technology research and development, our academic specializations and discreet confidentiality.

At present the main telecommunication products cover countries worldwide such as: Argentina, Australia, Austria, Belgium, Brazil, Columbia, Slovakia, Denmark, Finland, France, Germany, Greece, Holland, Hungary, India, Italy, Japan, Korea Poland, Saudi Arabia, South Africa, Sweden, Switzerland, U.S.A and the United Kingdom. All products have specific country quality assurance and authentication to meet the strict requirements of safety and environmental protection. Furthermore to meet the flourishing demand of the audio-visual market in recent years products have been developed in related cabling types such as USB, HDMI, and RCA to meet required market demand.

With reference to the ongoing demands our company has seen for products to support green environmental issues we are developing solar panels here in Taiwan for commercial and residential use. In cooperation with one of biggest Taiwan solar panel manufacturers we are developing solar panels system design and installation to meet rising consumer needs.

Education, Training and Skills of Team Members

The main engineering team are graduates in the fields of mechanical, electronic, and mathematics They all come from famous local schools of education including Nanchang university in Jiang’xi province, Wuhan university of electronic science and technology, Sichuan university of electronic science and technology, Foshan university in Guangdong province, Xiangtan college in Hunan province and Jiangxi college to name but a few. In total they have accumulated many years of practical experience and possess a wealth of knowledge and expertise in the various fields engineering.

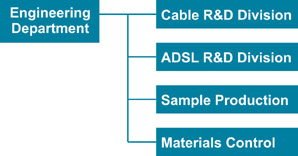

Organizational Framework

Cable R&D division:

Engage primarily in the development of network and communication products such as USB, HDMI, RCA and concentrate on the development of products to new specification and standards. We provide prototype and specific OEM/ODM designs to customer specifications and requirements.

ADSL R&D division:

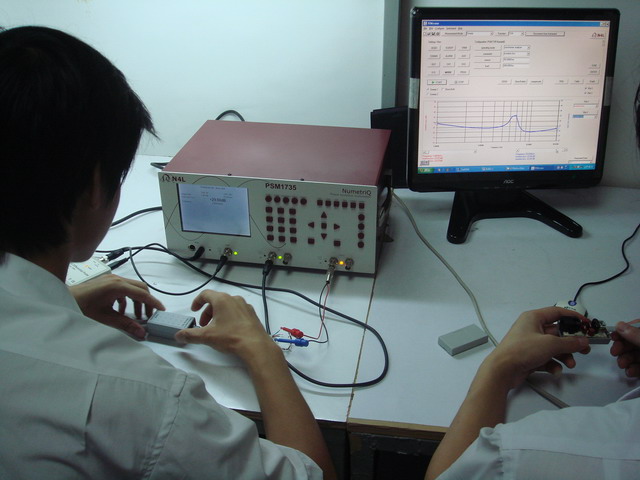

Meet the varying technological requirements of telecommunication products for various countries, through all the phases of research and development, testing, production. Working with our experienced teams we develop the core basis of digital technology products using our advanced and experimental facilities to guarantee the high quality of the technology and products.

Sample production:

We provide fast sample delivery of new development products for customers, with strict quality control on all aspects of procedures of production, test, and inspection to achieve our goal of a 0% defective rate.

Materials control:

Acknowledge and manage the requirements of specified material and drawings, establishing product structure with bill of material (BOM), plan the production line process, draw up SOP criterion, prepare operating instructions, ensure the management of equipment calibration and assist in the smooth functioning of the production line flow.